DiFeng Composite Co.Ltd(Nanjing)

Telephone:86-025-57450287

86-025-57450153

Fax:025-57450153

E-mail:nanjingdifeng@163.com

Address:Baima Industrial Park, Lishui District, Nanjing City, Jiangsu Province

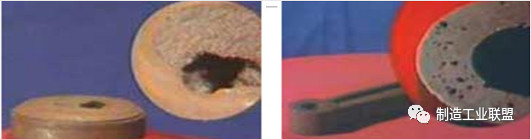

Hole defects are common defects in foundry production and one of the major losses to the foundry. Hole-like defects are classified into pores and shrinkage holes. Most of the pores are due to intrusion, entrapment, and entrapment of gas in the molten metal.

Below, let's look at the stomatal characteristics generated by different reasons:

(2) Intrusion pores : The pores produced by the type, core, paint, core support and cold iron invade the surface layer of the casting to form pores, which are mostly pear-shaped or elliptical, with large size, smooth pore walls and oxidized color on the surface.

Cause of formation

(2) The type, the core is not fully dried, the gas permeability is poor, the ventilation is poor, the moisture content and the gas-generating substance are too much, the paint is not dried or contains too much gas-generating component, the cold iron, the core support has rust spots, oil stain or unbaked Dry, poor metal exhaust, forming intrusive pores in the casting.

(4) The alloy liquid is easy to inhale, and no effective refining, protection and purification measures are taken during the smelting and pouring process, so that the molten metal contains a large amount of gas, slag and gas entrained components, which are formed during filling and solidification. The pores and reaction pores are separated.

(6) The pouring temperature is too low, the metal type temperature is too low, the molten metal is poorly slag-removed, and the viscosity is too high, so that the gas entangled in the pouring and filling process and the gas precipitated from the molten metal cannot be discharged out of the mold or floated. Go to the riser or the air outlet.

(8) Resin sand resin and curing agent are added in too much, the resin fluorine content is too high, the angular coefficient of raw sand and reclaimed sand is too high, the particle size is too fine, the amount of ignition and the content of fine powder are too high, so that the gas generation amount of the molding sand Too high, too low breathability

Prevention method

(2) Prevent the metal liquid from excessive oxidation and inhalation during the smelting process, deoxidize, degas and remove the slag, and apply a solvent to the surface of the molten metal pool in the ladle to prevent secondary oxidation, inhalation and return of harmful impurities. Molten pool. When aluminum is used to deoxidize cast steel and cast iron, the residual aluminum content should be strictly controlled. The molten steel with a strong tendency to inhale should be avoided by aluminum deoxidation. AVD, VOD, porous plug blowing inert gas, dusting method, etc. can be used. The molten steel is refined outside the furnace to remove the gas and harmful impurities in the molten steel. For the ductile iron, the desulfurization should be strengthened to reduce the flow rate of the original soup. Under the premise of ensuring spheroidization, the amount of the spheroidizing agent can be reduced as much as possible. The amount of residual magnesium in the cast iron is enhanced and inoculated.

(4) When casting, it should ensure that the mold and core exhaust are unblocked, and the exhaust channel should be opened in the sand core. When the mold is combined, the core gap should be filled to avoid the drilling of the molten metal to block the exhaust passage.

(6) Reducing the amount of resin and curing agent added to the resin sand, using low- or no-nitrogen resin and round and reclaimed sand with round shape, moderate particle size, low amount of ignition and low content of fine powder to reduce the gas generation of the resin. To improve the breathability of resin sand

There are many reasons for the shrinkage and shrinkage of castings. There are reasons for the design of castings and patterns, the reasons for the improper design of the flask, the reason for the design of the riser, the reasons for the displacement of the sand, and the system. The reasons for this are the reasons for the improper mixing of metal chemical components, the reasons for improper operation of the melting section, and the reasons for pouring.

Due to the numerous causes of shrinkage of castings, it is often time consuming to find the root cause. How to quickly determine the internal cause of shrinkage of castings, which requires us to compare the case of shrinkage defects in castings, memorize theoretical features, and strengthen learning, so as to improve the ability to understand and solve such defects.

scan