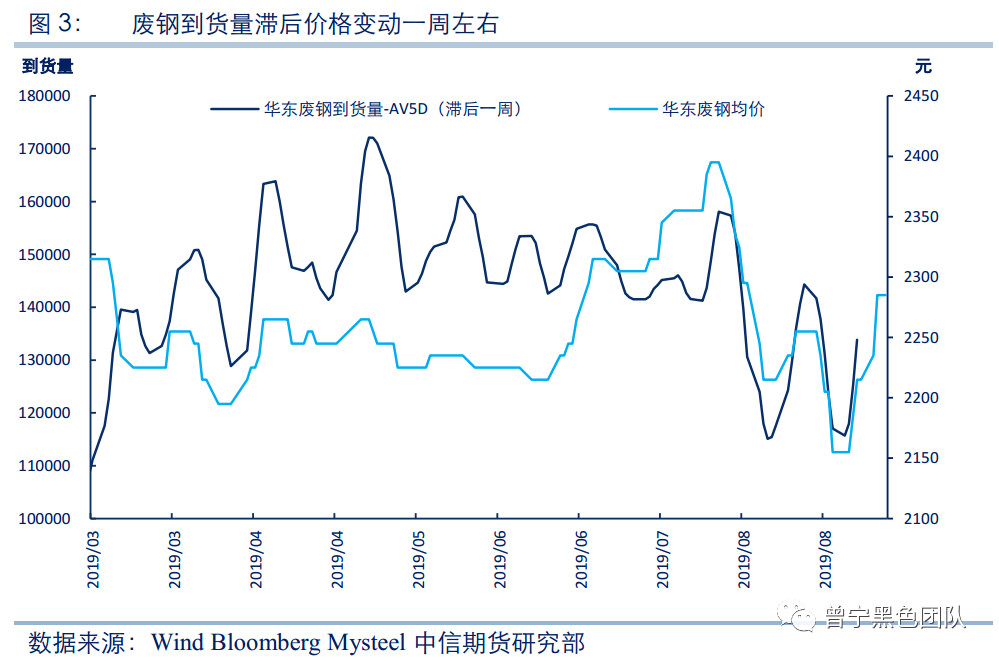

The tight supply of scrap is a reality. The surveyed production companies generally reported that the scrap supply has decreased significantly this year, and the monthly scrap supply has fallen by 20% year-on-year. The inventory of electric furnace enterprises surveyed is currently at the lowest level in history and can only maintain normal turnover. Traders generally feedback that the volume of scrap received has declined to varying degrees, and stocks have declined.

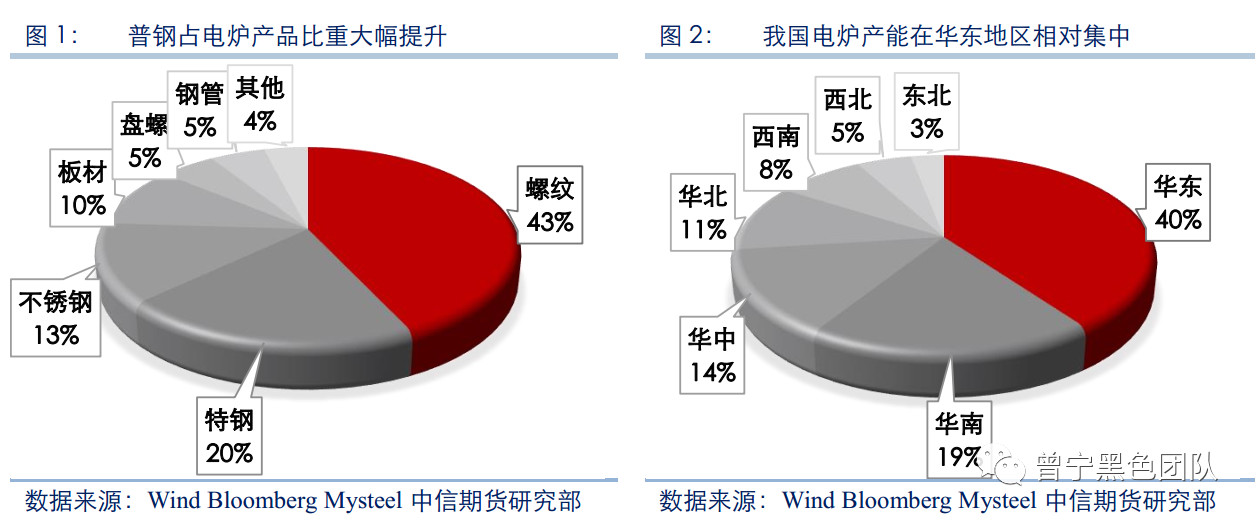

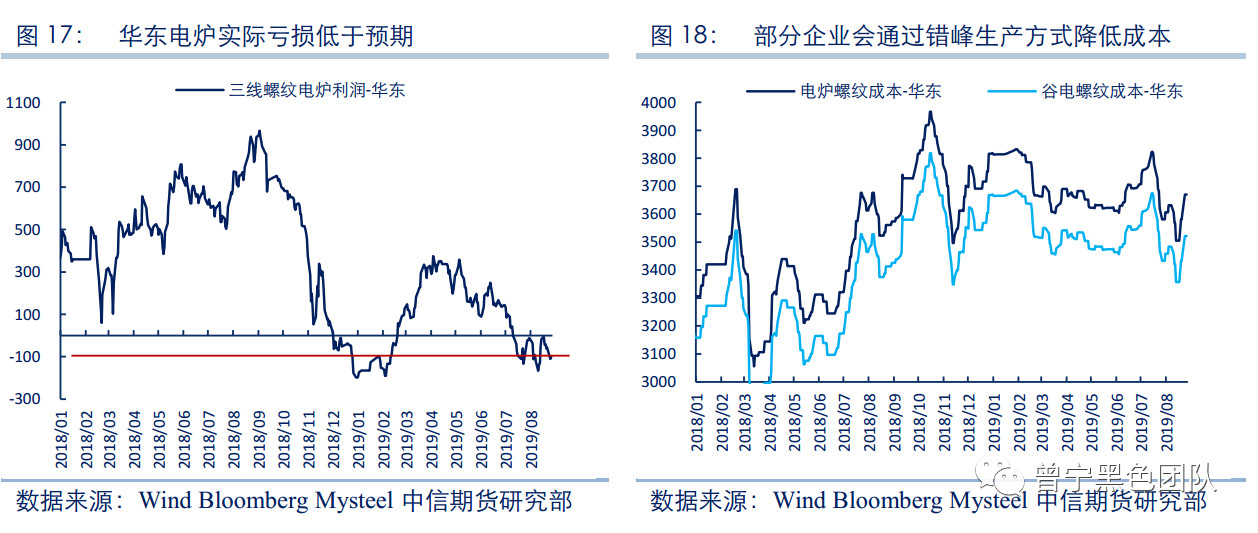

The actual electric furnace production in East China was better than expected. The government's tax rebate and rebate discounts have reduced the losses of electric furnace enterprises to a certain extent; enterprises will also reduce costs by optimizing operational procedures, improving production technology, and selecting low-cost raw materials; some enterprises on the edge of break-even have adopted peaks. The way of production reduces costs.

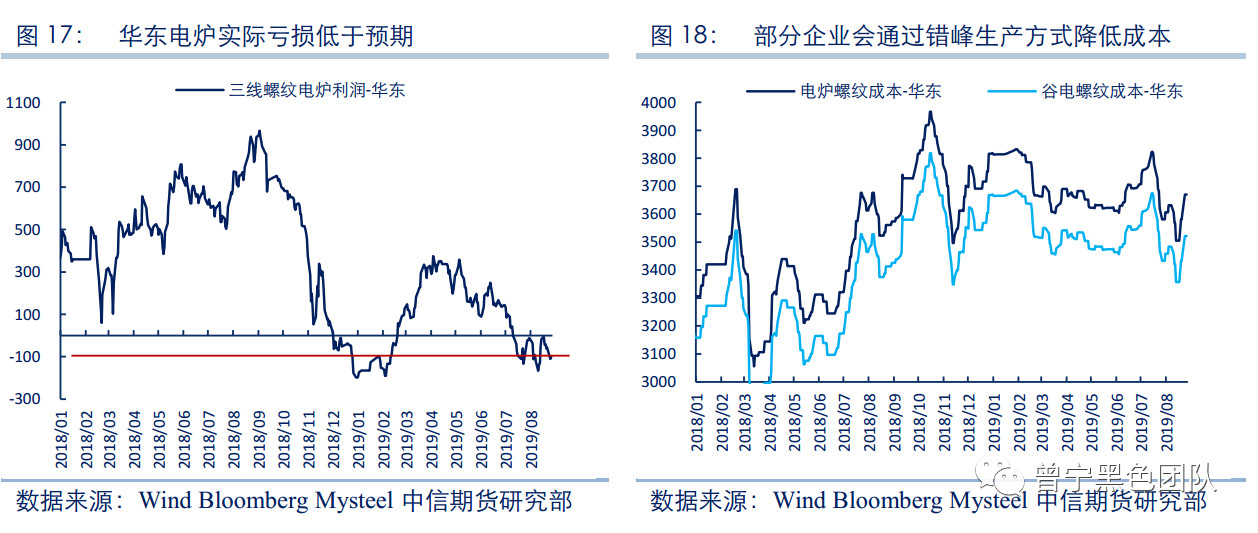

text

First, the tight supply of scrap in East China actually exists.

Fubao data shows that the current steel scrap inventory and the recent arrival of scrap in the country are significantly lower than the same period last year, which is consistent with the situation in East China, which can confirm that the scrap supply this year is indeed tight.

Second, the main reason for the tight supply and demand pattern of scrap steel

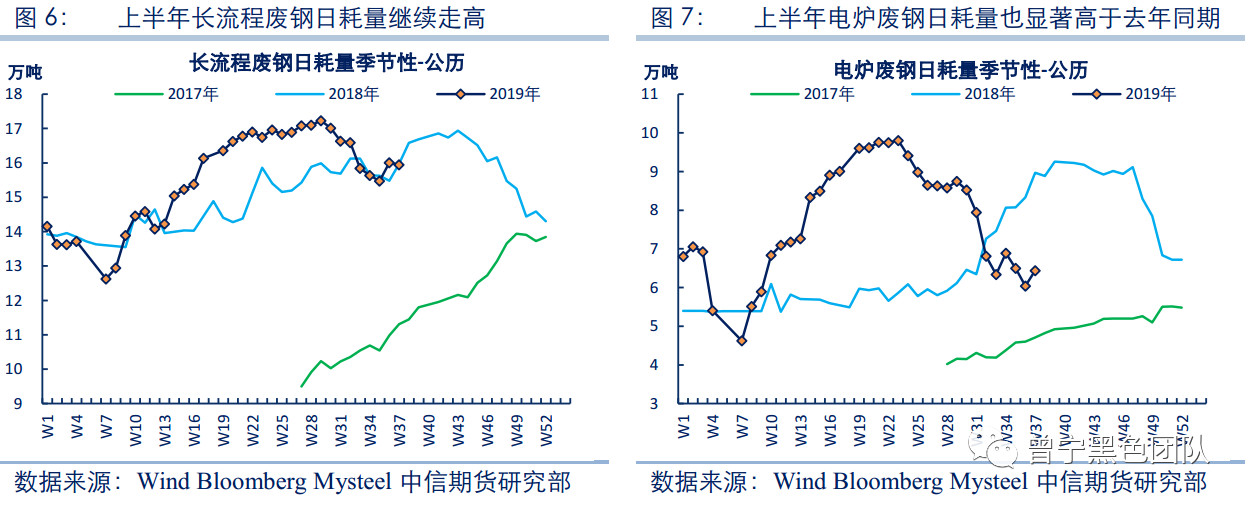

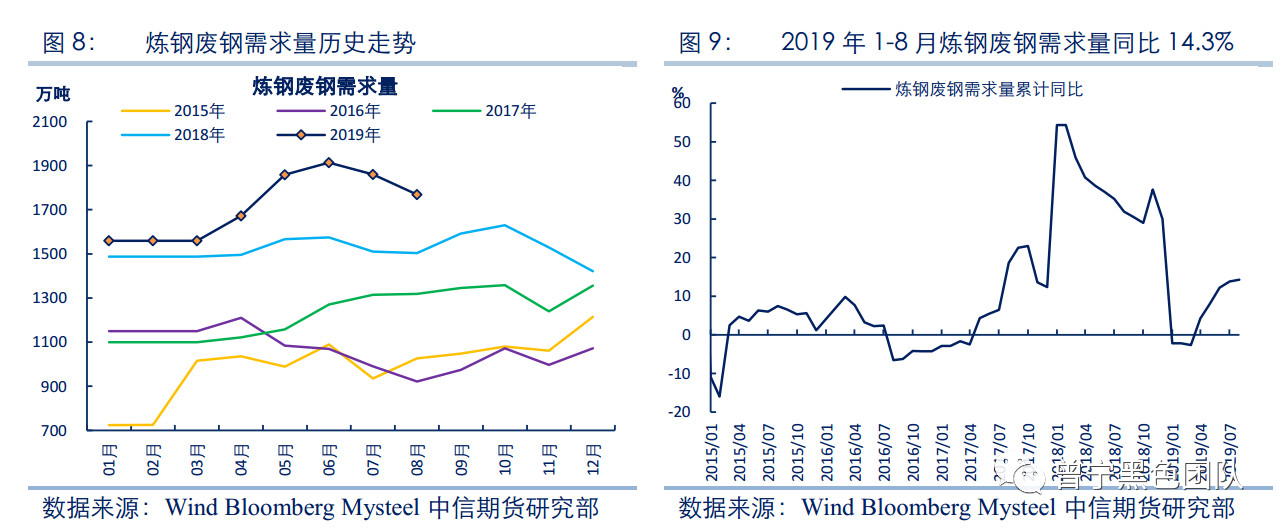

1. Significant increase in scrap demand

For steel companies, the main source of scrap can be divided into self-produced scrap, recycled scrap and imported scrap. In recent years, the amount of imported scrap has gradually shrunk. The total import volume in 2018 is only 1.08 million tons, which is negligible. Self-produced scrap, that is, scraps, tails, chips and other scraps produced by steel enterprises in steelmaking, rolling, etc., self-produced scrap generally does not enter the social circulation link, steel mills can achieve 100% recycling of such scraps. use. Recycling scrap can be divided into processed scrap recovered from manufacturing companies and depreciated steel purchased from society. Depreciation and scrapping of construction, automobiles, machinery, etc. are the largest sources of scrap, but they are also the most difficult part of recycling.

Self-produced scrap mainly relies on crude steel production. In 2001, self-produced scrap accounted for 8.8% of the crude steel output. After the production process progressed, the finished product rate gradually increased, and the self-produced scrap rate showed a year-on-year decline. In 2017, it gradually stabilized at around 5%. In the past two years, the crude steel processing technology has not improved much. Therefore, we assume that the self-produced scrap rate will remain at 5% from 2018 to 2019. After calculation, the supply of self-produced scrap has shown a steady increase, 2019-1 The cumulative year-on-year growth rate in August was around 7.7%.

The reduction in the source of scrap is mainly reflected in the reduction in recycled scrap. Among them, the processing scrap is mainly the scrap produced by the downstream manufacturers of steel in the production and assembly process, mainly from the production workshops of the automobile, home appliance, machinery and other manufacturing industries. This part of the scrap recycling is relatively difficult and the quality is good, so the recovery rate It is also relatively high. Due to the sluggish manufacturing industry this year, the processing scrap from manufacturing enterprises has been significantly reduced. In particular, the production of automobiles with more scraps during production and processing has been in a negative range for the year-on-year growth, and construction machinery sales have turned from May. Negative growth has all contributed to the supply of processed scrap. The surveyed enterprises reported that the processing scrap of Xuzhou Group and other manufacturing enterprises fell by about 20%, which caused a substantial drag on the steel scrap purchases.

Social depreciation scrap generally comes from the demolition of construction industry, the expiration of machinery and equipment, and the ship-breaking. The supply depends mainly on China's steel stock, so the scrap increase provided by this part has also stabilized for a long time. there are increasing trend, but this year has been a series of new influence of interference factors: According to research by the feedback shantytowns plan before halving and are concentrated in the July of this year, the recent heavy demolition waste was significantly reduced; shipbreaking need Oxygen propane cutting is greatly affected by environmental protection this year; the difference in car sales can also be interpreted as the car elimination is less than expected, and the previous car engine is not allowed to be used twice, but the engine can be recycled after the policy adjustment this year, so no Re-formed scrap. The above factors have a certain inhibitory effect on the growth rate of socially depreciated scrap. The reduction in processing scrap and the slowdown in the growth of socially depreciated scrap have led to a slowdown in the source of scrap.

3. A series of new changes in the behavior pattern of the scrap industry

(2) According to the investigation of the electric furnace steel mills, after the government cracked down on the strip steel, the recycling of scrap steel became more profitable. The number of traders who purchased scrap in the past two years increased significantly. This aspect will lead to more diversified resources and increase the difficulty of acquisition; on the other hand, it will lead to fierce competition among traders (6 scrap purchase companies in a small town), and scrap processing profits from 200-300 yuan in 2017/ The ton is squeezed to 20-50 yuan/ton, and scrap processing is currently in a small profit state.

(4) As mentioned above, once the steel mill suppresses the scrap price, the liquidity of the scrap will deteriorate rapidly. According to research feedback, local electric furnace manufacturers have tried to combine peak production and suppress scrap prices by reducing the demand for scrap, but failed to do so.

4, environmental protection efforts to enhance the impact of scrap supply

5. The impact of seasonal factors is weaker than expected

Third, the tight pattern continues, scrap and steel will be transferred to positive feedback

Looking back at the negative feedback between steel and scrap in August, that is, the demand for steel is not good - the profit of steel is falling - the daily consumption of scrap is falling - the price of scrap is falling - giving up the space for steel to fall. We believe that breaking the negative feedback requires steel demand to rebound. From the market performance at the end of August and the beginning of September, the trend of demand recovery has already formed, and there are certain signs of exceeding expectations. Last week, the apparent consumption of rebar was close to 4 million tons. After the steel mill's profits rebound, the daily consumption of scrap will also rise, and the steel and scrap will be transferred to positive feedback, that is, the steel demand will rise - the steel profit will rise - the daily consumption of scrap will rise - the scrap price will rise - the cost of the electric furnace will move up. The cost of electric furnaces has strengthened the support for steel prices. According to our previous estimates, the demand for steel terminals in September-October will be good. It is expected that positive feedback will continue and the spot of scrap will continue to perform strongly.

Fourth, the actual electric furnace production situation in East China is better than expected

According to a company with relatively strong competitive advantage, in addition to government subsidies, enterprises will reduce costs by optimizing operational procedures and improving production techniques. The selection of raw materials also tends to choose relatively cheap materials, scraps, etc. Through the quality control of the acquisition link, the water use rate of light and thin materials can also reach a high level of 92.5%. Therefore, this year, except for the loss of production and the Spring Festival, the company can basically achieve 24-hour continuous production. It has a good profit from April to July. The profit and loss are basically balanced in August. At present, there are 80 yuan/ton. profit. The company said that if the loss reaches 100 yuan / ton, it will consider production suspension or peak production.

However, the continuous squeeze of profits has also narrowed the short-process output. At present, the capacity utilization rate of 53 independent electric arc furnaces counted by Mysteel has shrunk to a low level of 48.73%. Our research found that the actual production situation in East China is better than expected. Therefore, it is expected that there will be little room for further decline in short-term process output in the short term, and it may gradually stabilize in the positive feedback of scrap steel prices.

However, the continuous squeeze of profits has also narrowed the short-process output. At present, the capacity utilization rate of 53 independent electric arc furnaces counted by Mysteel has shrunk to a low level of 48.73%. Our research found that the actual production situation in East China is better than expected. Therefore, it is expected that there will be little room for further decline in short-term process output in the short term, and it may gradually stabilize in the positive feedback of scrap steel prices.

Starting from CITIC Futures Report 20190918